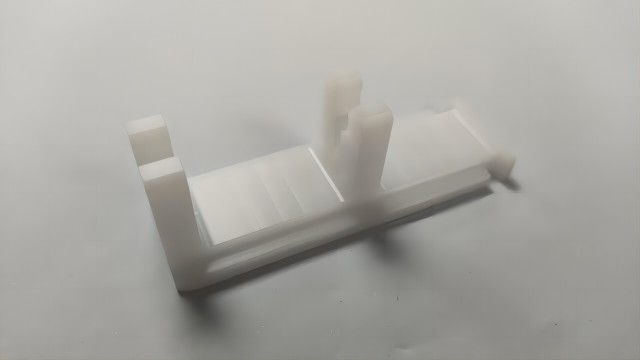

Ko da yakeInjin CNCna sassa na filastik yana da sauƙin yanke, yana da wasu matsaloli, kamar sauƙi nakasawa, ƙarancin zafin jiki mara kyau, kuma yana da matukar damuwa ga yanke ƙarfi, daidaiton sarrafa shi ba a tabbatar da shi ba, saboda yana da sauƙin kamuwa da yanayin zafi, kuma yana da sauƙin samar da nakasawa wajen sarrafawa, amma muna da hanyoyin da za mu bi don magance shi.CNC machining na filastik sassa:

1. Zaɓin kayan aiki:

• Kamar yadda kayan filastik ke da ɗan laushi, ya kamata a zaɓi kayan aiki masu kaifi. Misali, don samfuran filastik ABS, kayan aikin carbide tare da gefuna masu kaifi na iya rage yawan hawaye da burrs yayin aiki yadda ya kamata.

• Zaɓi kayan aikin bisa ga siffa da ƙaƙƙarfan ƙaƙƙarfan samfurin. Idan samfurin yana da ƙanƙantaccen tsarin ciki ko kunkuntar gibi, waɗannan wuraren za su buƙaci a ƙera su daidai ta amfani da ƙananan kayan aiki kamar ƙananan ƙananan ƙwallon ƙafa.

2. Yanke saitunan sigina:

• Gudun Yanke: Matsayin narkewar filastik yana da ƙarancin ƙarancin ƙarfi. Yanke da sauri na iya sa robobin ya yi zafi da narkewa cikin sauƙi. Gabaɗaya magana, yankan gudu na iya zama da sauri fiye da waɗanda ake kera kayan ƙarfe, amma yakamata a daidaita su bisa takamaiman nau'in filastik da yanayin kayan aiki. Misali, lokacin sarrafa samfuran polycarbonate (PC), ana iya saita saurin yanke a kusan 300-600m/min.

• Gudun ciyarwa: Gudun ciyarwa mai dacewa zai iya tabbatar da ingancin sarrafawa. Yawan ciyarwar abinci na iya haifar da kayan aiki don ɗaukar ƙarfin yanke wuce gona da iri, yana haifar da raguwar ingancin samfurin samfur; ƙananan adadin abinci zai rage yawan aiki. Don samfuran filastik na yau da kullun, saurin ciyarwa na iya zama tsakanin 0.05 – 0.2 mm/haƙori.

• Zurfin yanke: Zurfin yankan bai kamata ya kasance mai zurfi ba; in ba haka ba, za a haifar da manyan runduna masu yankewa, waɗanda za su iya lalata ko fashe samfurin. A karkashin yanayi na al'ada, ana ba da shawarar cewa a sarrafa zurfin yanke guda ɗaya tsakanin 0.5 - 2mm.

3. Zaɓin hanyar ɗaurewa:

• Zaɓi hanyoyin da suka dace don gujewa lalata saman samfurin. Za'a iya amfani da abubuwa masu laushi irin su faifan roba azaman layin lamba tsakanin manne da samfuri don hana lalacewa. Misali, lokacin danne samfuri a cikin vise, sanya takalmin roba akan muƙamuƙi ba wai kawai manne samfurin bane amma kuma yana kare saman sa.

• Lokacin danne, tabbatar da daidaiton samfurin don hana ƙaura yayin aiki. Don samfurori masu siffa ba bisa ka'ida ba, ana iya amfani da kayan aiki na al'ada ko haɗin haɗin gwiwa don tabbatar da tsayayyen matsayi yayin aiki.

4. Tsare-tsaren aiwatarwa:

Gabaɗaya magana, ana yin aikin injina da farko don cire yawancin alawus, barin kusan 0.5 – 1 mm alawus don kammalawa. Roughing na iya amfani da manyan sigogin yanke don inganta aikin sarrafawa.

•Lokacin da aka gama, ya kamata a biya hankali don tabbatar da daidaiton girma da ingancin samfurin samfurin. Don samfura tare da buƙatun inganci mafi girma, ana iya shirya tsarin ƙarshe na ƙarshe, kamar milling tare da ƙaramin saurin ciyarwa, ƙaramin zurfin yanke, ko amfani da kayan aikin gogewa don jiyya na saman.

5. Amfani da coolant:

•Lokacin sarrafa samfuran filastik, yi hankali lokacin amfani da coolant. Wasu robobi na iya amsawa da sinadarai tare da sanyaya, don haka zaɓi nau'in sanyaya da ya dace. Misali, don samfuran polystyrene (PS), guje wa amfani da na'urorin sanyaya da ke ƙunshe da wasu kaushi.

•Babban ayyukan sanyaya sune sanyaya da lubrication. Yayin aikin injin, mai sanyaya mai dacewa zai iya rage yawan zafin jiki, rage lalacewa na kayan aiki, da haɓaka ingancin injin.

Lokacin aikawa: Oktoba-11-2024