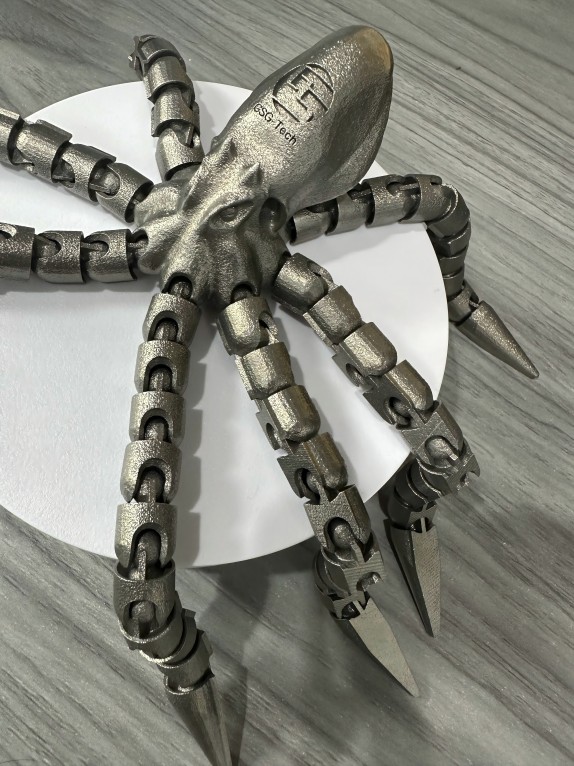

Kwanan nan, mun yi nuni na karfe3D bugu, kuma mun kammala shi cikin nasara, to menene karfe3D bugu? Menene fa'ida da rashin amfaninta?

Ƙarfe 3D bugu wani ƙari ne na masana'anta da ke gina abubuwa masu girma uku ta hanyar ƙara kayan ƙarfe ta Layer. Anan ga cikakken gabatarwar ga bugun 3D na ƙarfe:

Ƙa'idar fasaha

Zaɓin Laser sintering (SLS): Yin amfani da katako mai ƙarfi na Laser don zaɓar narke da sinter ƙarfe foda, dumama kayan foda zuwa zafin jiki kaɗan ƙasa da wurin narkewa, ta yadda za a sami haɗin ƙarfe tsakanin ɓangarorin foda, ta haka ne za a gina abu Layer ta Layer. A cikin aikin bugu, sai a fara dasa wani nau'in foda na karfe a kan dandalin bugawa, sannan kuma na'urar Laser ta duba foda daidai da sigar abin da aka yi masa, ta yadda foda da aka tantance ta narke sannan ta dahu tare, bayan kammala wani bugu, sai dandali ya sauke wani nisa, sannan sai a yada wani sabon foda, a sake maimaita abin da ke sama har sai an buga dukkan abin.

Zaɓaɓɓen Laser Melting (SLM): Kama da SLS, amma tare da mafi girma Laser makamashi, da karfe foda za a iya gaba daya narke don samar da wani m tsarin, mafi girma yawa da kuma mafi inji Properties za a iya samu, da kuma ƙarfi da daidaito na buga karfe sassa ne mafi girma, kusa da ko ma wuce sassa samar da gargajiya masana'antu tsari. Ya dace da sassa na masana'antu a sararin samaniya, kayan aikin likita da sauran filayen da ke buƙatar babban daidaito da aiki.

Electron biam melting (EBM): Yin amfani da igiyoyin lantarki a matsayin tushen makamashi don narke foda na karfe. Itacen lantarki yana da halaye na ƙarfin ƙarfin ƙarfi da saurin dubawa, wanda zai iya narkar da foda na ƙarfe da sauri kuma ya inganta ingantaccen bugu. Bugawa a cikin yanayi mara kyau zai iya guje wa amsawar kayan ƙarfe tare da iskar oxygen yayin aikin bugu, wanda ya dace da bugu na alloy titanium, alloy na tushen nickel da sauran kayan ƙarfe masu kula da abun ciki na oxygen, galibi ana amfani da su a cikin sararin samaniya, kayan aikin likita da sauran manyan filayen.

Metal abu extrusion (ME): Material extrusion tushen masana'antu Hanyar, ta hanyar extrusion shugaban extrude karfe abu a cikin nau'i na siliki ko manna, kuma a lokaci guda don zafi da warkewa, don cimma Layer ta Layer tara gyare-gyare. Idan aka kwatanta da fasahar narkewar Laser, farashin saka hannun jari yana da ƙasa, mafi sassauƙa da dacewa, musamman dacewa da haɓakawa da wuri a yanayin ofis da yanayin masana'antu.

Kayan gama gari

Titanium gami: yana da abũbuwan amfãni daga high ƙarfi, low yawa, mai kyau lalata juriya da biocompatibility, yadu amfani a cikin sararin samaniya, likita kayan aiki, mota da sauran filayen, kamar jirgin sama engine ruwan wukake, wucin gadi gidajen abinci da sauran sassa masana'antu.

Bakin karfe: yana da kyakkyawan juriya na lalata, kayan aikin injiniya da kaddarorin sarrafawa, ƙarancin farashi, yana ɗaya daga cikin abubuwan da aka saba amfani da su a cikin bugu na 3D na ƙarfe, ana iya amfani da su don kera sassa daban-daban na inji, kayan aiki, na'urorin likitanci da sauransu.

Aluminum gami: low yawa, high ƙarfi, mai kyau thermal watsin, dace da masana'antu sassa tare da babban nauyi bukatun, kamar mota engine Silinda block, Aerospace tsarin sassa, da dai sauransu

Alloy na tushen nickel: tare da kyakkyawan ƙarfin zafin jiki, juriya na lalata da juriya na iskar shaka, ana amfani da shi sau da yawa wajen kera manyan abubuwan zafin jiki kamar injin jirgin sama da injin turbin gas.

amfani

Babban digiri na 'yanci na zane: Ikon samun nasarar samar da sifofi masu rikitarwa da sifofi, irin su tsarin lattice, ingantattun tsarin da aka inganta, da dai sauransu, waɗanda suke da wahala ko ba za a iya cimma su ba a cikin hanyoyin masana'antu na gargajiya, suna ba da mafi girman sararin ƙirƙira don ƙirar samfuri, kuma yana iya samar da sassa masu sauƙi, manyan ayyuka.

Rage adadin sassa: sassa da yawa za a iya haɗa su cikin gaba ɗaya, rage haɗin haɗin gwiwa da tsarin haɗuwa tsakanin sassa, inganta ingantaccen samarwa, rage farashin, amma kuma inganta aminci da kwanciyar hankali na samfurin.

Samfur da sauri: Yana iya samar da samfurin samfur a cikin ɗan gajeren lokaci, haɓaka zagayowar haɓaka samfuran, rage farashin bincike da haɓakawa, da kuma taimakawa kamfanoni su kawo samfuran zuwa kasuwa cikin sauri.

Abubuwan da aka keɓancewa: Dangane da buƙatun mutum na abokan ciniki, ana iya kera samfura na musamman don biyan buƙatu na musamman na abokan ciniki daban-daban, masu dacewa da ƙirar likitanci, kayan ado da sauran filayen da aka keɓance.

Iyakance

Ingancin yanayin ƙasa mara kyau: Ƙaƙƙarfan sassa na sassa na ƙarfe da aka buga yana da girma sosai, kuma ana buƙatar magani bayan magani, irin su niƙa, gogewa, sandblasting, da dai sauransu, don inganta yanayin ƙare, ƙara farashin samarwa da lokaci.

Lalacewar ciki: za a iya samun lahani na ciki kamar su pores, abubuwan da ba a haɗa su ba, da rashin cika fuska yayin aikin bugu, wanda ke shafar kaddarorin injinan sassan, musamman a cikin aikace-aikacen babban kaya da nauyin hawan keke, ya wajaba don rage abin da ya faru na lahani na ciki ta hanyar inganta sigogin tsarin bugawa da kuma ɗaukar hanyoyin da suka dace bayan aiwatarwa.

Ƙayyadaddun kayan aiki: Ko da yake nau'ikan kayan bugu na 3D na ƙarfe da ake samu suna ƙaruwa, har yanzu akwai wasu ƙayyadaddun ƙayyadaddun kayan aiki idan aka kwatanta da hanyoyin masana'anta na gargajiya, kuma wasu kayan ƙarfe masu ƙarfi sun fi wahalar bugawa kuma farashi ya fi girma.

Matsaloli masu tsada: Farashin kayan aikin bugu na 3D na ƙarfe da kayan yana da inganci kuma saurin bugu yana jinkirin, wanda ba shi da tsada kamar yadda tsarin masana'antu na al'ada don samar da babban sikelin, kuma a halin yanzu ya fi dacewa da ƙaramin tsari, samarwa da aka keɓance da wuraren da babban aikin samfur da buƙatun inganci.

Ƙimar fasaha: Ƙarfe 3D bugu ya haɗa da sigogi masu rikitarwa da tsarin sarrafawa, wanda ke buƙatar masu aiki masu sana'a da goyon bayan fasaha, kuma yana buƙatar babban matakin fasaha da ƙwarewar masu aiki.

Filin aikace-aikace

Aerospace: An yi amfani da shi don kera injin injin injin, fayafai na injin turbine, tsarin reshe, sassan tauraron dan adam, da sauransu, wanda zai iya rage nauyin sassa, inganta ingantaccen mai, rage farashin samarwa, da tabbatar da babban aiki da amincin sassa.

Mota: Kera mota injin Silinda toshe, watsa harsashi, sassa tsarin sassa, da dai sauransu, don cimma nauyi ƙira na motoci, inganta man fetur da kuma aiki.

Likita: Samar da na'urorin likitanci, haɗin gwiwar wucin gadi, orthotics na hakori, na'urorin likitanci da za a iya dasa su, da dai sauransu, bisa ga bambance-bambancen mutum na marasa lafiya da aka keɓance masana'anta, haɓaka dacewa da na'urorin likitanci da tasirin magani.

Manufacturing ƙura: Manufacturing allura molds, mutu simintin gyaran kafa, da dai sauransu, gajarta da mold masana'antu sake zagayowar, rage halin kaka, inganta daidaito da kuma rikitarwa na mold.

Lantarki: Ƙirƙirar radiators, harsashi, allon kewayawa na kayan lantarki, da dai sauransu, don cimma haɗin gwiwar masana'antu na hadaddun sifofi, inganta aiki da tasirin zafi na kayan lantarki.

Kayan ado: Bisa ga ƙirƙirar mai ƙirƙira da buƙatun abokin ciniki, ana iya kera kayan ado iri-iri na musamman don haɓaka haɓakar samarwa da keɓancewar samfur.

Lokacin aikawa: Nuwamba-22-2024